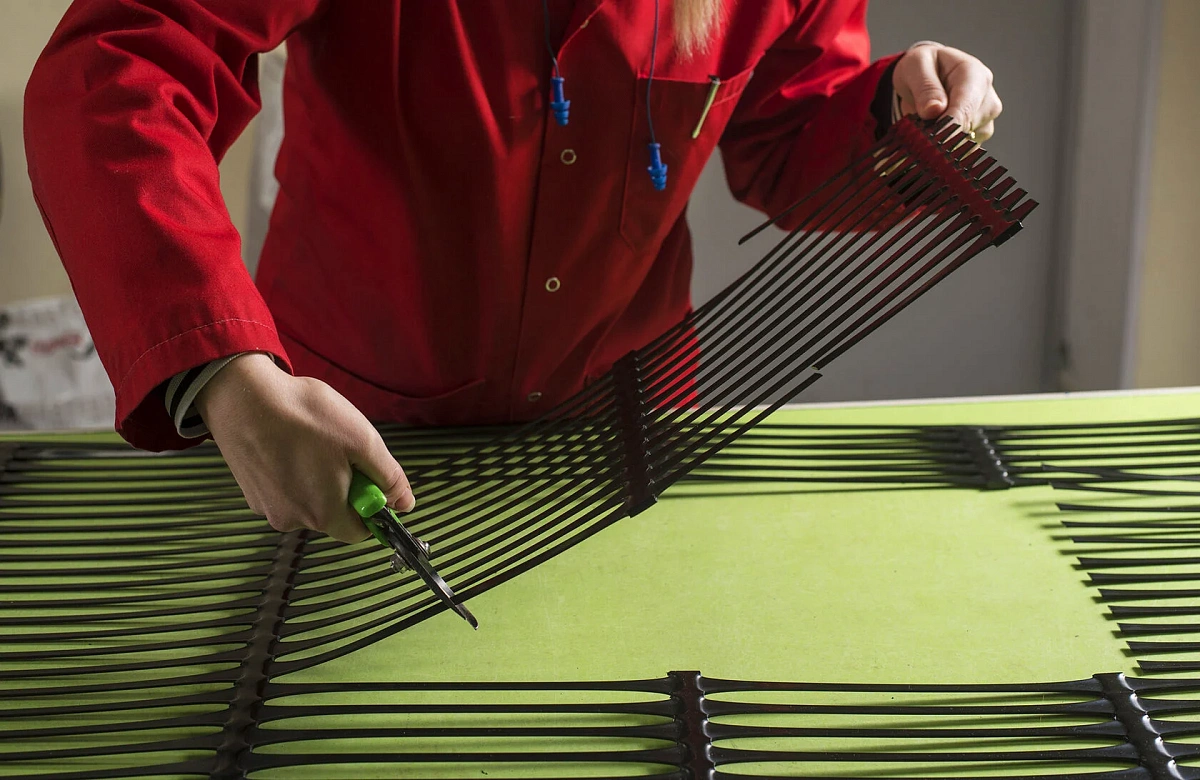

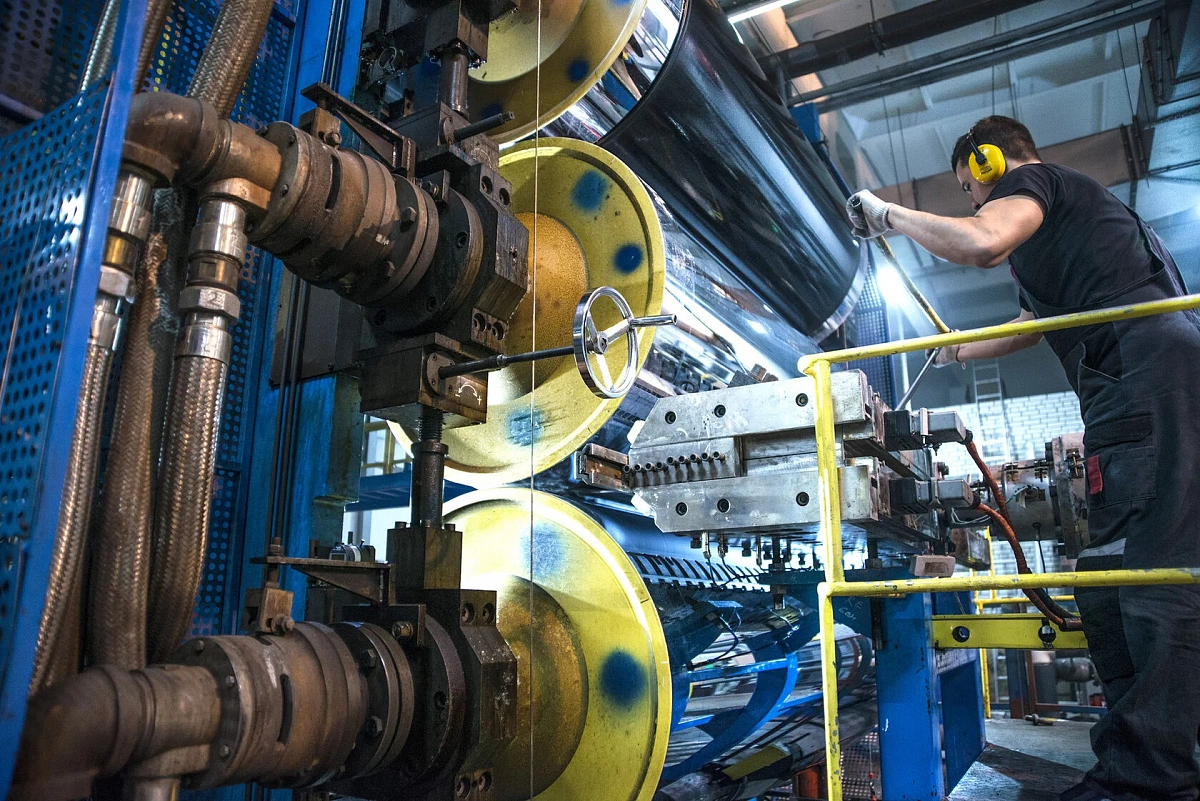

began working in Russia in 2011 as a joint venture of Tensar and local partners. Many team members have been designing and promoting Tensar technologies since 1996, after these solutions first came to the Russian market via distributors. In 2014 the company started manufacturing of innovative TriAx (TX), RE, and SS geogrids at its new plant in St Petersburg. At present the company provides supplies to the largest federal road and infrastructure projects in Russia and CIS and continues to expand its operations

The team which worked under the Tensar brand in the markets of Russia and CIS now operates under the new name – Soterra Engineering.

We continue offering our clients proven engineering solutions and the same range of top quality geosynthetic materials

-

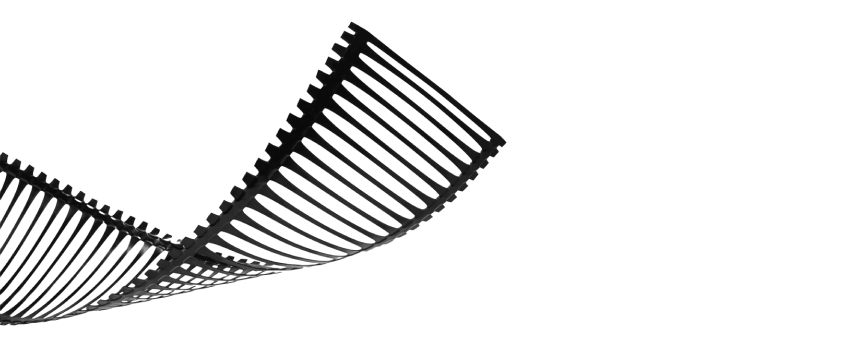

TriAx (TX)

-

RE

-

SS

-

GlasstexGrid

-

Modular concrete blocks TW1

-

Geopanels - Welded Steel Mesh

-

Reinforced concrete blocks

Soterra Engineering are a leader and expert in technology driven solutions for ground stabilisation and soil reinforcement. Soterra Engineering supplies geosynthetic products and provides proven practical solutions for poor soil conditions which can greatly impact upon the cost of railways, roads, and paved areas. Soterra Engineering also offers products for earth retaining walls and slopes, subgrade improvement and stabilization, foundations, reinforcement of asphalt to extend the life of pavements and erosion protection products for soil slopes and waterways.

SOLUTIONS

Soterra Engineering’s solutions (previously Tensar) are widely used in transport and infrastructure projects for:

-

Subgrade mechanical stabilisation in complicated geological conditions

-

Erosion control

-

Improving the durability of protective structures

-

Shoreline protection, Scour control, Marine foundation improvement

-

Reinforced Soil Retaining Walls & Slopes, Bridge abutments, Steep slopes

-

Pavement optimisation

-

Rail trackbed support and improvement

-

Working platforms for heavy-duty equipment, traffic, and storage

-

Asphalt reinforcement, asphalt pavement improvement

Sectors

-

Roads and Highways

-

Ports & Warehouses

-

Mining

-

Energy

-

Commercial & Industrial

-

Military Construction

-

Railways

-

Airports

-

Bridges

-

Landfill

-

Oil & Gas

-

Ports, Marine & Waterways

The Soterra Engineering Difference

- Proved costs and time reductions by 30-40%

- Road lifecycle costs reduction

- Extending pavement life

- Reducing CO2 emissions

- Maintenance cost reduction

PROJECTS

Since 1996 we completed over 10 000 projects in Russia and CIS, including such as:

1998 -2021 Project List is provided upon request.

Please see below a few video-cases of our completed projects.

Team

Soterra Engineering has three sites in Russia – plant in St Petersburg and two engineering and project support offices in Moscow and St Petersburg. The company employs over 60 people.

-

Guseva General Director -

Vachnadze Director for Business Development -

Raudanen Sales Director -

Sakaev Technical Director -

Astakhov Area Director, Central Federal District -

Egorov Area Project Manager -

Smirnov Area Project Manager -

Ostrovsky Area Project Manager -

Vissarionov Area Project Manager -

Vershinin Area Project Manager -

Alibegov Area Project Manager -

Lenin Area Project Manager -

Kalugin Lead Engineer -

Solovyev Lead Engineer -

Kiselev Lead Engineer -

Kuznetsova Lead Engineer -

Petrov Engineer -

Simonov Engineer -

Podstrechny Engineer -

Korovin Engineer

Contacts

- 8 800 551-81-81 for toll free calls from Russia

- 8 812 677-07-94 for calls from CIS and other countries

- info@soterra.ru

-

Offices:

- St Petersburg, Vvedenskaya ul., 21

- Moscow, Nizhnaya Krasnoselskaya ul., 13, bld. 1

-

Plant:

- St Petersburg, Astronomicheskaya ul., 8, bld. 2B